Evaporation is a fundamental process in many industrial applications, from refrigeration to chemical processing. At the heart of this process is the industrial evaporator coil, a critical component that plays a major role in the efficient transfer of heat. This article will delve into the mechanics of how an industrial evaporator coil functions, its applications, and the various factors that influence its efficiency.

Understanding the Basics of Evaporator Coils

An industrial evaporator coil is essentially a heat exchanger. It works by absorbing heat from a substance, typically a liquid or a gas, causing the substance to evaporate. In the realm of refrigeration, for example, the evaporator coil houses a refrigerant that absorbs heat from the environment and evaporates, thus cooling the surrounding area.

The design of these coils is crucial for their efficiency. Typically made from materials with high thermal conductivity, like copper or aluminum, the coils are designed to maximize surface area, allowing for more effective heat absorption. The structure and layout of the coil, including the number of turns in the coil, can greatly influence its performance.

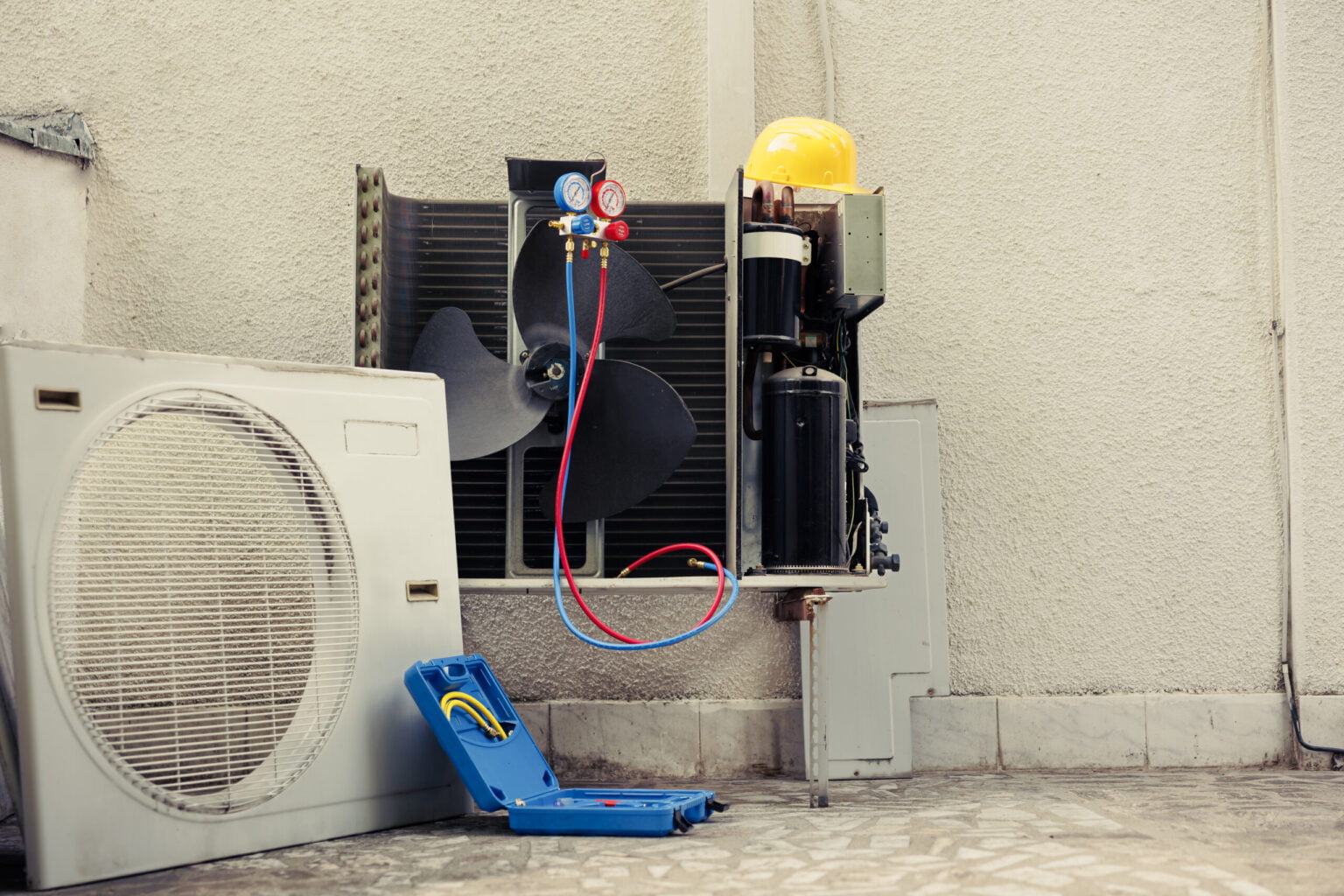

Role in Industrial Refrigeration

In industrial refrigeration systems, the evaporator coil is where the refrigerant absorbs heat and transitions from a liquid to a gas. This process is essential for cooling large spaces, such as warehouses or food storage facilities. The efficiency of this process is not just a matter of temperature control but also impacts energy consumption and operational costs.

Maintenance and cleanliness of the coil play a significant role in its performance. Dirt, dust, and other contaminants can insulate the coil, reducing its ability to absorb heat effectively. Regular cleaning and maintenance are thus crucial to keep these systems running efficiently.

Heat Transfer and Efficiency

The efficiency of an industrial evaporator coil is largely determined by its ability to transfer heat. Factors like airflow, coil design, and the properties of the refrigerant all play a role in how effectively heat is absorbed and transferred. Proper airflow around the coils is critical, as it allows the absorbed heat to be efficiently dissipated.

Moreover, the type of refrigerant used can affect the overall efficiency of the coil. Refrigerants with a higher heat absorption rate can improve the performance of the system, though environmental and safety considerations are also important factors in the selection of a refrigerant.

Applications Beyond Refrigeration

While typically associated with refrigeration, industrial evaporator coils have a broader range of applications. They are used in air conditioning systems, where they extract heat from the air to cool buildings. In the chemical industry, these coils are used in processes where controlled evaporation is required, such as in the concentration of solutions.

Their use in waste treatment plants is also noteworthy. Here, evaporator coils are used to evaporate water from waste, reducing its volume and making it easier to manage. This process is not only important for waste reduction but also plays a role in the recovery of valuable substances from waste streams.

Factors Affecting Longevity and Performance

The longevity and performance of an industrial evaporator coil depend on several factors. Material corrosion is a significant concern, especially in environments where the coil is exposed to corrosive substances or extreme temperatures. Using corrosion-resistant materials or coatings can help mitigate this.

Another factor is the mechanical design of the coil. Evaporator coils that are designed to minimize stress and strain during operation are less likely to suffer from fatigue and mechanical failure over time. This design consideration is especially important in applications where the coil is subjected to frequent temperature fluctuations.

The Importance of Optimal Operation

Overall, the industrial evaporator coil is a significant component in a wide range of industrial applications. Its ability to efficiently transfer heat not only ensures the effectiveness of processes like refrigeration and air conditioning but also plays a vital role in energy conservation and operational cost reduction. Understanding the factors that affect the performance and longevity of these coils is key to maintaining their efficiency and reliability. Regular maintenance, proper design, and the right choice of materials and refrigerants are essential to ensure these systems operate at their best.